The act of separation of the different elements from the mixture is called a filtration method. For these industries select the fiberglass filter paper and other filtration material. Filter papers are taken in the use of qualitative analysis and quantitative analysis. Qualitative analysis is performed by using the Whatman filter paper.

Fiberglass materials are produced by taking different ratios, and proportions can be formed in different ways. Depending on the ratio and quality, the fiberglass is implemented in bathtubs, boats, aircraft, etc. Fiberglass is a very lightweight material that is used for residential and commercial purposes.

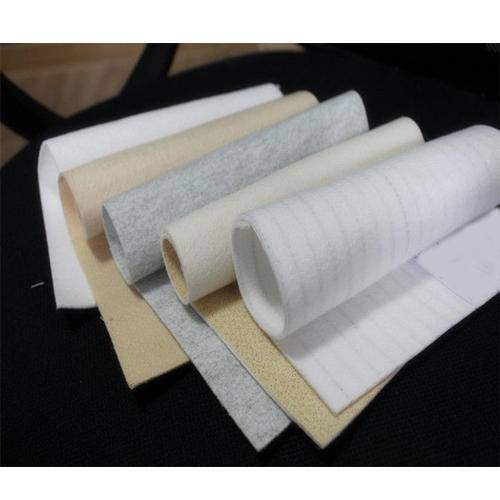

Many fiberglass filter manufacturer firms are supplying fiberglass made products like fiberglass filter cloth, fiberglass filter paper, fiberglass filter bag, etc.

General info about Whatman filter and normal filter

Whatman filter paper is designed for a specific purpose with the cellulose fiber material. High-quality alpha linters is the primary raw material to raise the bar of alpha-cellulose. We can say that a huge amount of alpha-cellulose material is involved in the Whatman filter paper.

To differentiate the quality of the Whatman filter many factors are determined by the filter manufacturer such as retention, thickness, weight, etc. It starts from grade 1 to infinity. These filters come with high-absorbing quality. So it does not let the unwanted material across the filter media.

A chemical resin is available to attain this level of wet-capability.

Normal filter paper is designed to filtrate the particles from the liquid medium. This filter paper is also known for the high-absorbent capacity, permeability, magnitude, size, volumetric passage rate, etc. The two variants are available for this type of filter paper.

One is used to perform the process of qualitative analysis. This produces a low amount of unnecessary material that is around 0.13%.

The other one is used to perform the quantitative analysis, after cleaning and analysis, this paper will produce 0.0009% of the dust in the end. Because of this feature, the paper is considered a dust-free analysis paper.

Comparison of Whatman filter to normal filter

To perform qualitative analysis, Whatman filter paper is available in the filtration industry. It is designed by a specific machine using a specific ratio and proportion. It meets the specific requirement and guidelines of qualitative analysis. After the analysis, the dust percentage will be calculated at around 0.13%.

While the normal filter paper is not a fully permeable material but it can absorb a quite amount of liquid and airflow. It is quite efficient to separate the particles and pollutants from the liquid solution. The normal filter is efficient and advantageous for both analysis processes- qualitative and quantitative. Here it makes a difference from the Whatman filter paper in the analysis procedure.

The grade of filter paper plays an important role in the overall analysis process so one should use it after the proper inspection of the grade. The dust waste percentage will stay between 0.0009% to 0.13% in both qualitative and quantitative. Depending on the purpose and material of the chemical the researchers decide the grade of the filter.

Filter papers will block the path to affect the quality of liquid and airflow in the chemical industry and makes the process of quality assurance successful.

Characteristics of Fiberglass filter paper

Fiberglass offers high-performance, high-quality based mechanical strength, the resistance capacity is far better than the steel material.

Fiberglass material offers premium quality insulation.

The structure of fiberglass is made with minerals so it is fully unaffected by fire and sparks. It does not react to any flame events. Fiberglass products are not the fire agents while it is released freely no explosion event occurs.

Fiberglass can’t scale or stretch because of the high-temperature and moisture content. The linear expansion rate is minor in fiberglass material.

Fiberglass materials are segmented into different sizes and prices, you can associate the product with any of the resins, cement products. No compatibility issues have been seen.

Fiberglass products are rigid materials so neither insects nor rodents can bite and cut them. It is very hard for them.

Fiberglass products can be efficiently implemented at construction sites or commercial places; it does not conduct thermal energy.

Fiberglass materials are suitable for electromagnetic windows.

Classification of Fiberglass filter paper

Below we are defining the class type of fiberglass.

A-glass

Alkali glass is recognized as A-glass. It does not get affected by chemicals. The material is glass fiber perfect for the process equipment.

C-glass

This class is known as Chemical glass because it is sustainable by the chemical effect.

E-glass

This fiberglass material is not affected by electricity so it is a perfect insulator.

AE-glass

AE glass is segmented as alkali glass.

S-glass

S-glass fiber is known for its high-quality mechanical properties.

These filter papers are available in the manufacturing firm involved in Cotton filter cloth, fiberglass filter cloth production. Visit the place that produces sustainable, durable, high-quality filter products at affordable rates and complete the lab process.